SUNY chemists seek to scale patented process

In the summer of 2008, SUNY Oneonta’s Jacqueline Bennett was trying to create a classroom experiment to teach her students about imines, a family of compounds that contains a double bond between carbon and nitrogen. Instead, she invented a chemical process that has the potential to revolutionize pharmaceuticals, agrochemicals, household products, and plastics manufacturing.

“I started with one green solvent that gave a really high yield, but the quality wasn’t very good,” says Professor Bennett, who has made more than 300 imine compounds using the new process, with new ones coming every few weeks. “Next, I chose a different green solvent and got the opposite results: great quality but terrible yield. I realized if I could somehow combine the two, there was a chance I could make the ideal solvent – or something that produced terrible quality and terrible yield, which isn’t what happened at all. We got great quality and great yield, and the first time we tried, I almost missed the reaction entirely. I was writing in my notebook, I looked up, and the reaction was done. It turned out to be the perfect solvent.”

Following further experimentation, Bennett received a patent on the process, which is a major improvement over conventional methods that require significantly more time and energy to create products far less pure and using far more hazardous methods. She began working with Judy Albers, who leads SUNY Geneseo’s VentureWorks program, along with Geneseo Associate Professor Eric Helms and a team of Geneseo undergrads, whose 2017 proposal earned second place in the New York Business Plan Competition’s energy and sustainability track. The $5,000 prize provided the team with the capital needed to create a company, which they call Verdimine, to commercialize the technology. Bennett and Helms lead Verdimine’s research and development team.

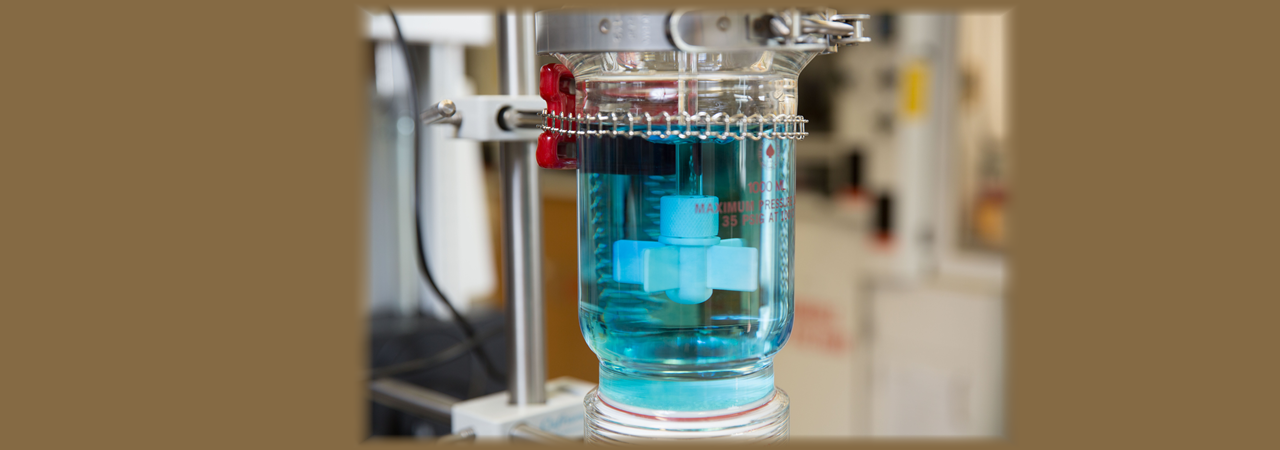

Now, with a 2018 investment from the SUNY Technology Accelerator Fund (TAF), which helps faculty scientists turn their research into market-ready technologies, Verdimine is attempting to increase production from lab-scale to manufacturing-scale.

The production scaling project is progressing as planned. “From one to five grams, we’ve scaled up to 100 grams and had absolutely no surprises,” says Helms. “The timeframe is exactly what we expected, and with the materials and equipment from this TAF investment, we should be easily able to scale up to the quantities industry needs to evaluate our samples. This is definitely something chemical companies will be interested in. When I first saw how quickly the process goes, how clean the products come out, and how little energy is needed, I really got excited about the possibilities. And I’m even more excited about the possibility of going bigger.”

There’s good reason to be excited. More than 80% of waste, 60% of energy, and 50% of greenhouse gases in producing pharmaceuticals are related to solvents, which are generally derived from petroleum and require days of high-temperature processing to produce a low yield of imines that need to be purified and recrystallized before becoming usable. Those complications make imines very expensive to synthesize, and because 5% of drugs currently on the market are manufactured with imines, those expenses – plus the long-term costs of toxic byproducts and hazardous waste – represent an enormous hurdle in bringing new medications to market.

By contrast, Bennett’s process uses ethyl lactate, a solvent that’s stable, biodegradable, renewable, and approved by the Food and Drug Administration as a food additive. The reactions occur at room temperature, requiring only minutes to complete, and their only byproduct is water, resulting in a substantial savings in energy, time, and expense, and earning Bennett honors as the Eastern New York Intellectual Property Law Association’s 2016 Inventor of the Year.

“This wasn’t my original plan,” says Bennett, whose undergraduate research group, Building a Legacy of Outstanding New Developments and Excellence in Science (BLONDES) continues to produce new compounds. “This is really important chemistry to show students, and I was just trying to design an experiment to use in a teaching lab, where there’s not enough time for hours and hours of boiling. I wasn’t expecting this at all, because reactions don’t normally happen this fast, especially at room temperature. And once you create these compounds, you can convert them into dozens of other useful compounds.”

Dr. Joseph Marasco, Verdimine’s CEO, has been successfully building businesses in the field of specialty and fine chemicals for 25 years. “Verdimine has quickly created a substantial set of proofs showing that our unique process is robust and clearly works. We plan to attack the market with the intent to replace certain current toxic and dangerous imine productions,” Marasco stated. “Also,” he says, “we have recently shown that entirely new molecules can be made using our system, opening the door for fertile new intellectual property. The gentle nature of the reaction also seems to protect the synthesis of complex and labile molecules which would be normally torn apart under the prior classic preparation methods. This vastly expands the applicability of Verdimine’s original intended system.”

“There’s so much potential utility to the type of compounds we’re making,” says Helms, whose other research focuses on the chemistry of plant species like pearly everlasting (Anaphalis margaritacea) and the invasive autumn olive (Elaeagnus umbellate). “The green chemistry we’re doing here fits well with my interests in natural products, environmental issues, and all the serendipitous things that happen when you’re least expecting them. This is a new problem to investigate, and I don’t think we’re even close to the end of what we’re able to do with these compounds. There’s a lot here, a lot of ground still to be covered.”

comments powered by Disqus