Aerogel Advance

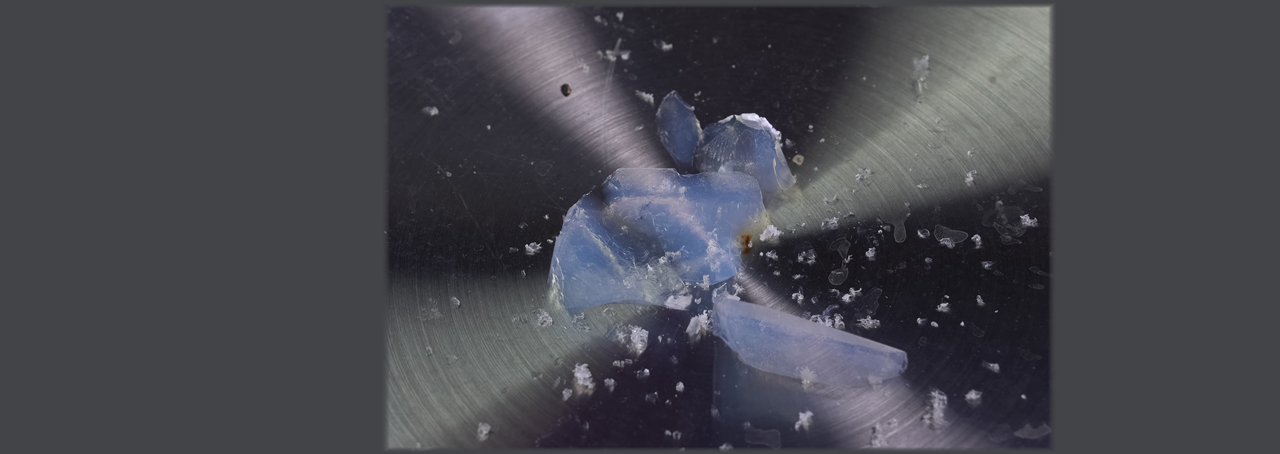

Frozen smoke, solid air, blue smoke: all are nicknames for aerogel, which is a synthetic ultralight material created by removing the liquid from a gel and replacing it with gas. What you get is a substance that is porous and has extremely low thermal conductivity.

For insulation, it’s all about R-value, which is a measure of thermal conductivity. The higher the value, the less thermally conductive and more effective the insulation is. In the standard equation, conductivity and thickness are combined into a single value that measures resistance. When multiplied by the area of your home, this produces the R-value of an insulation.

A materials science professor at the University at Buffalo (UB), Shenqiang Ren had the inspiration to modify aerogel to create a transparent, ultra-low conductive (and high R-value) version that is the ideal insulation. SUNY’s Technology Accelerator Fund (TAF) recently awarded him an investment to develop his idea and turn it into a marketable product.

Ren first got the idea for his invention from the structure of the pores of the human skin and how they regulate the body’s temperature. His invention is biomimetic, in that it imitates the pore structure and regulates temperature in a similar manner.

Aerogels have been used before, in applications such as space suits and the Mars Rover, but until now have been too expensive for large-scale corporate and industrial applications. The reason was that to create an aerogel, it has to go through a process known as supercritical drying, which involved pressurized CO2 chambers and expensive solvents. That drives costs to $16 per square foot.

Ren modified this process by brainstorming a different, ambient pressure drying approach that reduces costs substantially. This process takes place at atmospheric temperatures and pressure and can be performed on site. Instead of toxic solvents like methanol or hexane, the ambient approach uses only water, the world’s most abundant solvent, which is clean and renewable.

In addition to the TAF grant, this year the Department of Energy (DOE) awarded him a $1,875,000 grant to support the development of the technology.

Ren’s aerogel can be rapidly prototyped since it can be 3D printed to specifications, eliminating cutting, trimming, shaping and their related costs and waste. That makes it affordable for large buildings and vastly improves clean energy efficiency since eliminates toxic chemicals.

“We are proposing using 3D printing to print any complex-shaped insulation product,” he says. “In some applications the insulation product won’t have a sheet structure, it will be three dimensional, with complex geometry. You can print these in a very rapid way.”

Since the aerogel is transparent, it can be used to create solid pane windows and skylights, increasing energy efficiency. Other advantages are that it’s soundproof--while being thinner than acoustic insulation--and fire resistant to 1000 deg. C.

The SUNY Technology Accelerator Fund (TAF) helps SUNY faculty inventors and scientists along the curve of transforming their research into market-ready technologies. The TAF investment will enable Ren to create prototypes for demonstration and will help him spread the word to major corporations about the advantages of the invention. One way he foresees introducing it to the market is as a hybrid with standard insulation.

Dr. Ren earned his Ph.D. in Materials Science at the University of Maryland College Park, and then served as a postdoc fellow at Massachusetts Institute of Technology (MIT). He is the recipient of many awards, including a 2015 National Science Foundation – CAREER Award. He is also the North American editor of the Journal of Experimental Nanoscience, and editorial panel member of Scientific Report.

Ren is currently one of the researchers for the UB RENEW (Research and Education in eNergy, Environment and Water) Institute, which focuses on challenging energy and environmental issues, as well as their social and economic effects. The institute also works to create and manage leading edge research, education and outreach programs.

In 2018, Ren and his research partner Chi Zhou made the cut to become one of the top 25 semifinalists in the NASA iTech competition, which was developed to inspire ideas that will help future exploration in space and on Earth.

Dr. Ren will be preoccupied with the development and marketing of his aerogel technology for the near future, but the next project he would like to pursue is 3D printable electronics.

“I would like to transform all this fundamental science I’ve explored in recent years into real applications,” he says.

Ren's imagination, his collaborative finesse, his ability to conceive beyond standard boundaries, are prime examples of what makes the SUNY system the ideal community for innovation. His aerogel technology is a major step forward in creating the clean energy of the future. After all, the ultimate goal of advanced research should be to address social needs, to tend to the basic problems of humanity.

comments powered by Disqus