The search for a better catalyst

In 2015, Volkswagen was found guilty of clandestinely fitting nearly 600,000 cars sold in the United States with "defeat devices" that were designed to circumvent emissions tests. A desperate measure like this is a clear sign of the difficulty that many companies have in meeting increasingly stringent emission control standards.

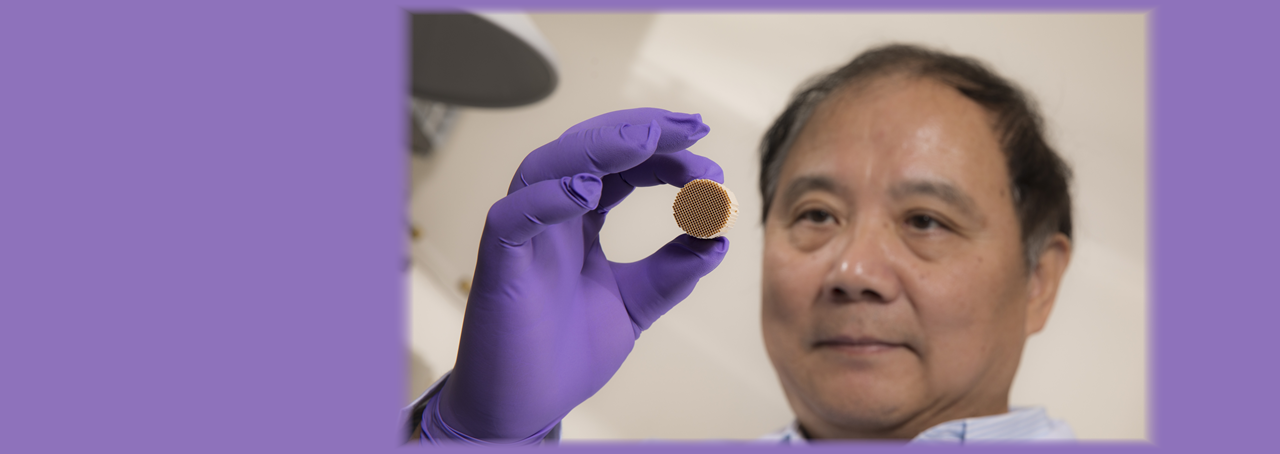

Chemist Chuan-Jian Zhong of Binghamton University began pondering on this problem years ago. Since catalytic converters require the use of expensive platinum group metals (PGM), and demand for them is constantly rising, how is it possible to keep costs down and still create an emissions catalyst that functions effectively?

His solution? A nanoengineered multimetallic alloy catalyst for emission control systems with drastically reduced PGM that operates at a far lower temperature (30-150 degrees C) than standard PGM-based catalysts. The concept would mean lower manufacturing costs and reduced toxic gases. Manufacturers could meet increasingly demanding emission standards and global air quality would improve.

Catalysts are substances that speed up chemical reactions while remaining unchanged by the process. They’re made of nondegradable metals like platinum or a platinum group metal such as palladium or rhodium. They’re essential in catalytic converters because exhaust gases only flow through the unit for a short time.

Inside the converter, the gases pass through a dense honeycomb made of ceramic and coated catalysts. The honeycomb design means as much of the exhaust as possible contacts the catalyst for quick, efficient conversion.

Zhong explains that a catalyst needs to operate at a low temperature because cold engines create the most toxic emissions. A catalyst must work quickly and efficiently at this level. “Most of your emission is created at home, near your garage,” he says.

Anticipating the possibilities of his idea, Zhong tendered a proposal to SUNY’s Technology Accelerator Fund, “Emission Control System Catalysts with Low Levels of Platinum Group Metals and Low Operating Temperature.” His research team was granted an investment to further develop the idea.

He accomplished his invention by combining PGM with lower cost metals at the nano level. The alloy was created through a combination of atomic mixing (Zhong calls it “chemical cooking”) and engineering from the atomic level up. Working at such an elementary particle level offers a stronger sense of control.

Once the alloy was created, there were more hurdles to overcome.

“One of the challenges of working at the nanoscale is that materials have the tendency to aggregate,” he says.

When a converter gets hot, metals clump up, which causes the device to detoxify less reliably. Zhong solved this by engineering the size, composition, distribution and stability of the individual nanocomponents on the ceramic converter surface.

Now that Zhong has a working prototype, the next challenge is one of resources for experimentation and finances for marketing.

The SUNY Technology Accelerator Fund (TAF) is helping with the next stage: finding major corporate partners to finance the idea. TAF was founded to help faculty inventors and scientists turn their research into market-ready technologies. The support TAF provides helps fill the gap between the end of government sponsorship and the securing of venture-capital support. Funding this transition is vital to delivering potentially beneficial ideas to a wider public.

For Zhong, the TAF grant will be seed money that allows his team to scale up production of samples, so that he can create quantity and evaluate the results. He’ll also need to see what potential partners such as Johnson Massey, Corning and BASF think of the invention.

“We’re currently interacting with a number of major companies, and we want them to evaluate it,” he says.

Zhong, a professor of chemistry and materials science, has worked in the fields of catalysis, materials, electrochemistry and advanced nanotechnology.

After he received his PhD from Xiamen University, he served as the Max Planck Society’s postdoctoral fellow at the Fritz-Haber Institute in 1989. Zhong then continued through postdoctoral work at the University of Minnesota and a position as associate scientist at Iowa State University/DOE-Ames Laboratory before joining the SUNY faculty in 1998. He has received an NSF CAREER award; the SUNY Chancellor’s Award for Excellence in Scholarship and Creative Activities; and 3M Faculty Research Award.

Zhong’s motivation has always been the investigation into mysteries in the laboratory. He thrives on the a-ha moment. One of his major influences was the late Alan MacDiarmid, chemistry professor at the University of Pennsylvania and a Nobel Prize winner in 2000. He inspired Zhong’s PhD work in conductive polymers, and they later coauthored a paper. These polymers showed promise for use in sensors and biosensors (which Zhong has also worked with) and helped inspire his current work at the molecular level.

Other than continuing to work on creating a commercially viable nanocatalyst, Zhong is interested in developing biomedical sensors using non-invasive nanotechnology, like an insulin tester that operates by sampling breath.

comments powered by Disqus